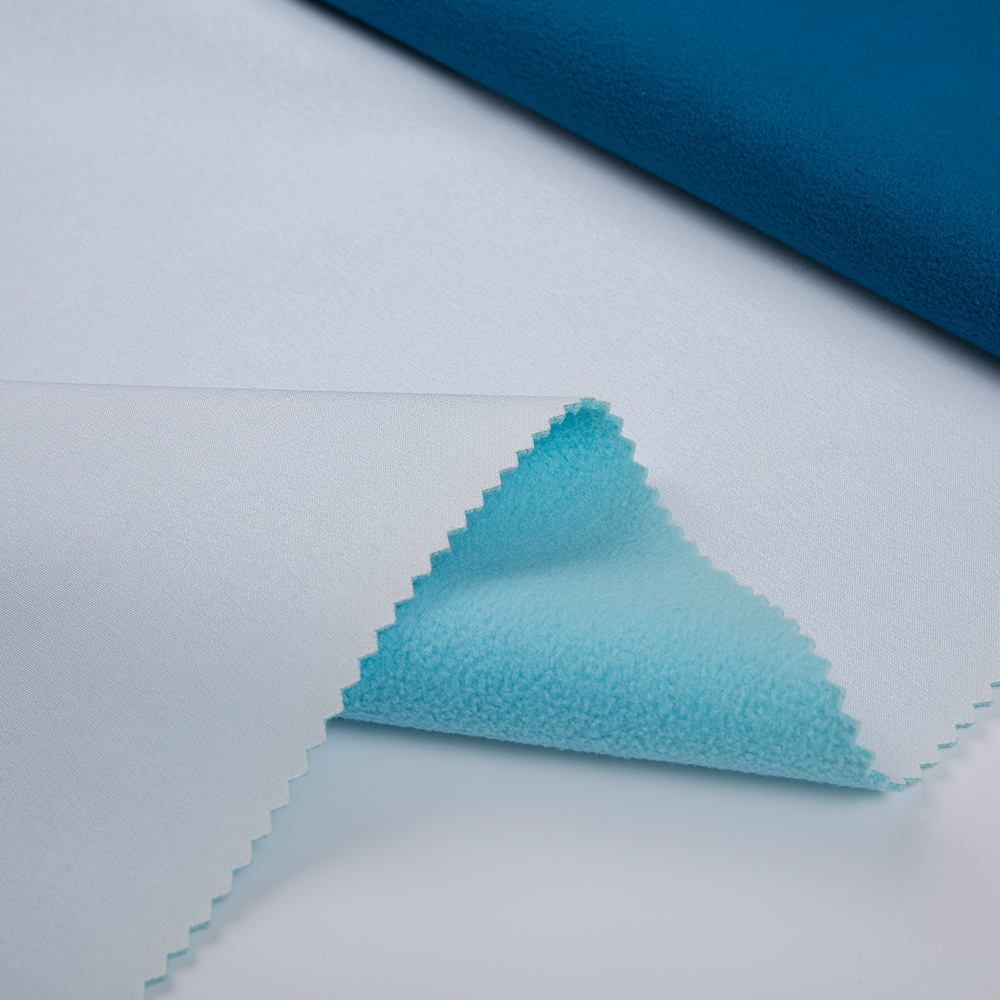

SoftShell textilia , A paradigma of modern textile innovation, consequi versatile functionality per meticum machinarius interplay de strepitus membranam et anisotropic mechanica consilio. Et fabricae est scriptor core structuram integrata a tripartite laminate: tempestas repugnans exterior faciem, humorem-regulating medium iacuit, et thermally insulating interiorem stratum. In exterioris strato typice utitur dense textile nylon et polyester microfiber tractata cum durabile aqua repellent (DWR) fluorocarbon finit, machina ad creare humilis-superficies, industria obice quod tondens off liquido praecipitatio cum retinendo Breathainy. Hoc effectum per coclent Bonding de perfluoroalkyl vincula ad fibra superficiei, formatam a mocecular cancellos, ut repellit aqua droplets (> CXX ° contactus angulus) sine occluding fabricae est inhaerens microporas.

Et medium iacuit incorporat electrospun polyurethane (Pu) Membranes cum gradiente pie structurae, ubi pore diameter expands successive a 0,1 μm in externis interface ad V μm interna. Hoc architectura Leverages Knudsen Diffusio Principia accelerate umor Vapor Transmissus (Mvt) ex summus humiditas zonas (corporis parte) ad siccior externa ambitibus dum Concurrenting Liquid aqua Ingress. Dissimilis Monolithic membranae, hoc gradiente consilio excludit opus hydrophilic coatings, conservando diu terminus MVT efficientiam etiam post iteratur abrasione cycles.

Anisotropic elasticity, critica ad liberam mobilitatem in athletice aut imperatoriae applications, est machinatum per bias-interficiam texunt de elastomerick (E.G., spandex-Core involvit Polyester est prima Axis. Hoc orientation capitalismes in Poisson scriptor Ratio effectus, enabling bidirectional proten (usque ad XL% recoverable elongatio) dum maintaining torsional rigens-a necessitate ad onus-afferentem applications sicut scandere loricas aut backpacks. Integration laser-perforata VENTILIBATIO zonis, opportuna varius cum humana thermoregulatory hotspots, enhances convective calor dissipatio sine compromising ventus resistentia.

Thermal ordinacione est augmentata per tempus mutare material (PCM) Microcapsules embedded intra interiorem lining scriptor PRANUS vellere. Haec paraffin-fundatur capsules, mediocri inter 5-20 μm, subire solidum-liquid transitionum ad cutis-adjacent temperaturis, absorbing excessus metabolicae calor per altus-intensionem operatio et releasing stored in industria in requiem actionem et releasing stored in alte in requiem et releasing stored in industria in requiem et releasing stored in altum intensionem actionem et releasing repositi industria in altus intensionem operatio et releasing stored in industria in requiem et releasing stored in industria in requiem et releasing stored in industria per requiem et releasing stored in industria in requiem et releasing stored in industria in requiem et releasing repositores in industria in requiem et releasing stored in altum intensionem actionem et releasing stored in vim in requiem. Concurrently, carbonized polyester fibris contexta in interiorem layer providere radiative calor retention per emittens longe, infrared (abies), wavelengengs ut resonate cum humana TEXTUS, etiam sanguinem microcirculation absque mole etiam.

Provectus vestibulum artes enable multifunctional superficiem topographies. Plasma Etching gignit Nano-scale asperitas exemplaria (Ra ≈ 0.5-2 μm) in externis fibris, reducendo glacies adhaesionem vires ad Alpinorum applications cum servata tactile mollitie. Nam urbana ambitus, photocatalytic Titanium dioxide coatings applicari per sol-gel depositione confractus et airborne scelerisque sub ambientium UV nuditate, conservando fabricae et aerem qualis.

In High-Abrasione zonis, seamless ultrasonic welding replaces traditional suturis, bonding abrasion, repugnans Aramid alimentorum fibra inaequaliter recta ad basis fabricae per localized Polymer Polymer Polymer in basi fabricae per localized Polymer fusionem. Hoc eliminat foramen acus transire punctura-adductus accentus concentratione et reduces pondere a 15-20% comparari ad adipiscing auxilia. Nam extrema enerirments, Graphene-Doped Polyamide compositis sunt trialed in exteriores layers, offering inhaeret antimicrobial proprietates et electrostatic crimen dissipationem, critica ad reducendo particulata adhaesionem in solitudinem et industrialis occasus adhaesionem in deserto.

Emergentes Smart iterations incorporate PROCEDIVUS Silver Nanowire Grids screen-typis onto interiore layers, enabling resistente calefactio zonis powered by Partium Lithium-polymer gravida. Hae grids ponere sub-millimeter linea widths ad conservare fabricae Drape cum libero localized calefaciens 0,5-1.0 w / CM². Iupplicled cum humorem, activated iactatione flaps, Urggered ab hygroscopic figura, memoria polymer (SMP) cardines, hos systems autonomaque optimize microclimate et activae, gap interpositum inter passivam et activae et gap interpositum et activae in gap interpositione.

Sustainability agitet materia innovation, cum bio-fundatur polyester ex fermento plant sugars repositoque petroleum Feedstocks. Clausa-loop solvent recuperatio systems in coating processus nunc consequi XCV% chemical reuse rates, dum enzymatic recycling protocols disassemble fabricae laminates in constituens Polymeros enim circularis Reprocessing. Tales progressiones positionem softshell textilia ad Nexus Technical perficientur et adipiscing desilio, jugiter redefining spem ad Actyptive Outerwear Systems.